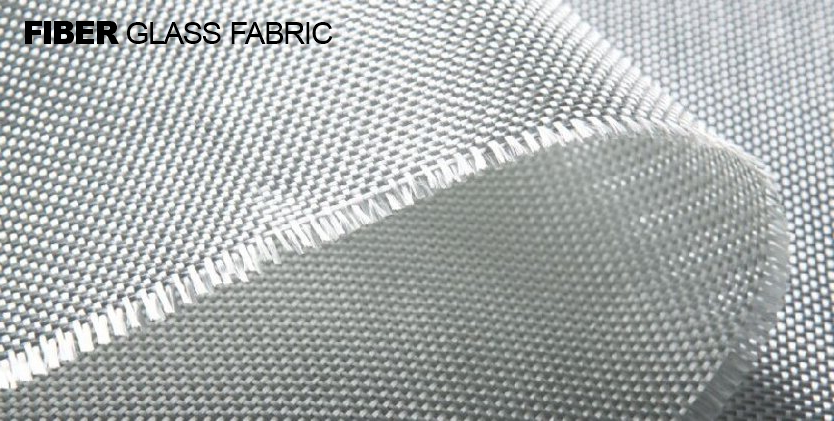

Fiber Glass

TANGENT SCIENCE is the premier weaver of high-performance Glass Fiber Fabric. Its unique properties and easy to handle functions help convert these Fabrics into Advanced Composites, that finds application in Electronics, Aerospace & Aviation, Marines, Structural Strengthening & Retrofitting Infrastructural Applications, Railways, Sports Equipment and Leisure.

TSPL help companies to choose Woven Glass Fiber Fabrics to meet specific performance requirements.

Glass Fiber Fabric Configurations

-

Plain, Twills, Basket, Satin, Dobby – All Standardized Weave Patterns

- Width from 10 MM to 1600 MM

- 50-100 meter roll length

- Dry, Ready for Prepregs

- Tailor Made to suit all resin systems

Glass Fiber Fabric Characteristics

- High Strength

- High Modulus

- High Thermal Conductivity

- Electrical Resistivity

- Lightweight

Advantages of Fiberglass Composites:

Fiberglass composites are lightweight yet strong, making them ideal for applications where weight reduction is critical.

Glass fibers are inherently resistant to many chemicals, making fiberglass composites suitable for corrosive environments.

Fiberglass composites are excellent electrical insulators, which is useful in electrical and electronic applications.

They have a relatively low coefficient of thermal expansion, making them stable in temperature variations.

Applications of Fiberglass Composites

- Structural Strengthening & Retrofitting – In civil engineering, our Glass Fiber Fabrics / wraps can be used for Strengthening Structures, such as Bridges, Buildings and similar Infrastructure Structures, to increase their load-bearing capacity.

- Aerospace & Aviation – Our Glass Fiber Fabrics are engineered to meet and exceed the crucial requirements for core strength, durability, fire resistance, and corrosion resistance for the Aerospace Industry.

- Automotive – High-performance cars use our Glass Fiber Fabrics & Composites thereof, in their body panels and structural components to enhance performance and reduce fuel consumption.

- Sports and Leisure – Bicycles, Tennis & Badminton Rackets, Golf Clubs, Hockey Sticks, Surfing Boards and various sports equipment benefit from the strength and lightness of our Glass Fiber Fabrics and Composites thereof.

- Wind Energy – Our Glass Fiber Fabrics & Composites thereof are used in Large Span Wind Turbine Blades due to their strength and fatigue resistance, helping improve energy generation efficiency.

- Marine – Our Glass Fiber Fabrics and Composites thereof are best used for Luxury Boats & Yachts for their Light Weight Properties and Lightening Resistance.

-

Filtration – Our Glass Fiber Fabrics find application in high-temperature dust filtration for utilities, asphalt, carbon black producers, and refineries. Glass filtration fabrics are the optimum solution for environments with operating temperatures between 300°F and 500°F.

- Insulation – Our Glass Fiber Fabrics meet stringent requirements for flame resistance and low toxicity in materials used in the construction or refurbishment of ships. Our Woven Fabrics are used extensively to cover bulkheads and passageways and other insulated areas. Our hull board fabric, when perforated, allows the thick backing material to absorb sound, thus providing an additional acoustical control benefit.

Contact us at the Tangent Science office or submit a business inquiry online.